| Sign In | Join Free | My carsrow.com |

|

- Home

- Products

- About Us

- Quality Control

- Contact Us

- Get Quotations

| Sign In | Join Free | My carsrow.com |

|

Brand Name : Custom LOGO

Model Number : HW-683

Certification : ISO9001

Place of Origin : China

MOQ : 1set

Price : 2000-10000USD/sets

Payment Terms : T/T , Paypal

Supply Ability : 50sets/month

Delivery Time : 25-40days

Packaging Details : wood carton, as customer requested

Product Name : Plastics Injection Moulds

Mold Design software : PRO/E, Solidwork, UG, Autocad, etc

Plastic Material : POM,PBT,PVC,HIPS,PMMA,TPE,PC/ABS, etc

Mould material : 45#, 50#, P20, 738, 738H,P20, NAK80, etc

Mould Cavity : 1*1,1+1,1*2,1+1+1,etc

Product weight : 1g-5kgs

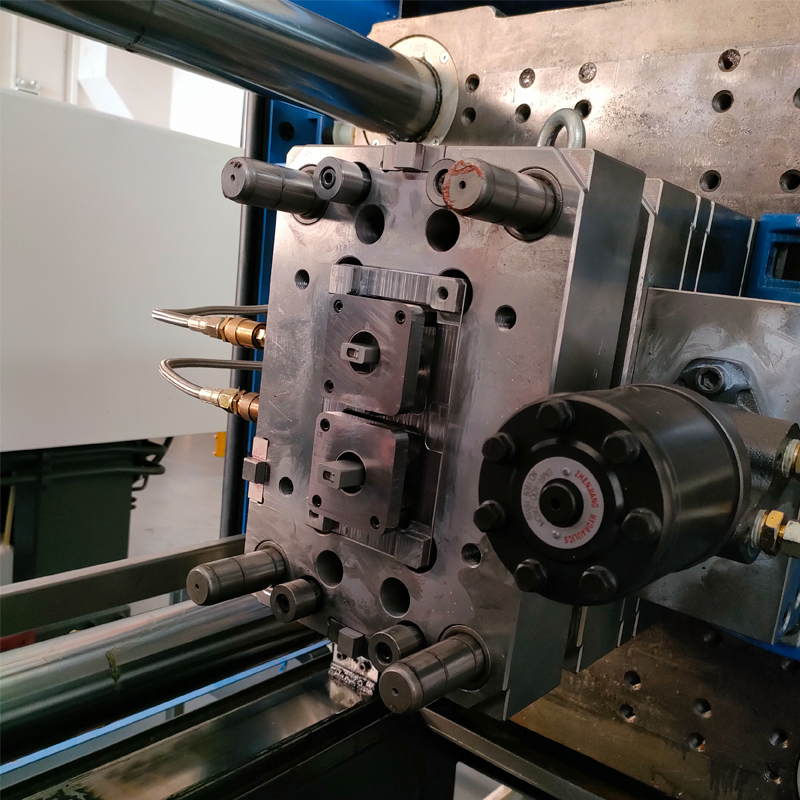

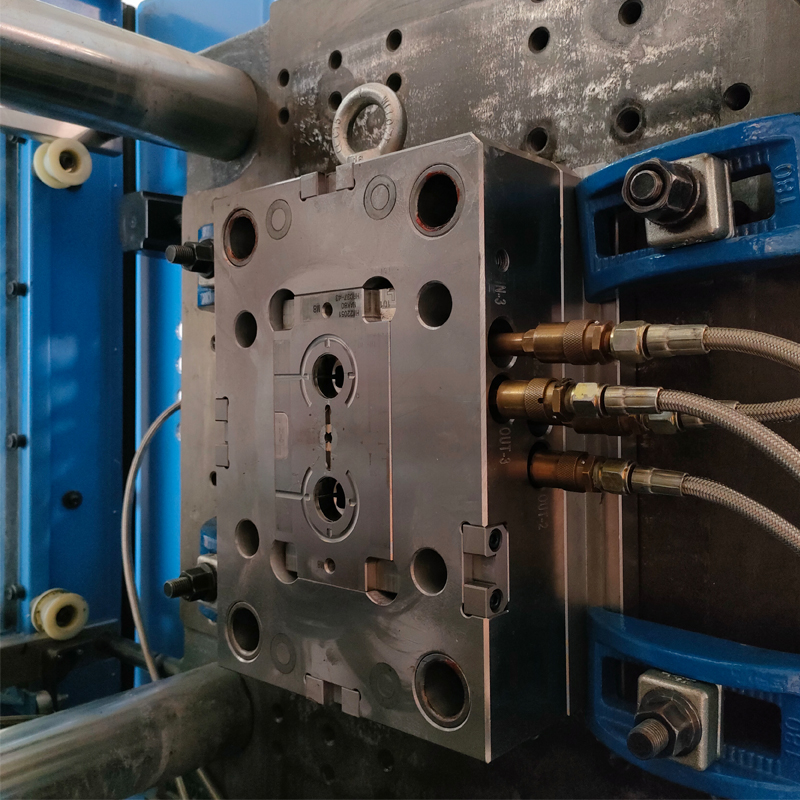

Custom PP Material Plastic Components Injection Molding For Mosquito Zapper

| Product name | Multi cavity hot runner injection mould supplier |

| Mould Material | P20,P20H,718,718H,738,738H,2316,M300,S136,S136H,NAK80,CR12,CR12MOV,SKD11,DF-2,SKS3,D2,SLD,DC53,H13,SKD61,2344,8407,HD,8418,FDAC,M2,SKH-9,SKH-51,M35,M42,ASP23 |

| Main Technology | Milling, grinding, CNC, EDM, wire cutting, carving, EDM, lathes, surface Finish, etc. |

| Base material | P20, 2738, 2344, 718, S136, 8407, NAK80, SKD61, H13 |

| Product Material | ABS,PP,PC,PA6,PA66,TPU,POM,PBT,PVC,HIPS,PMMA,TPE,PC/ABS, TPV, TPO,TPR,EVA,HDPE,LDPE,CPVC,PVDF |

| Main Technology | Milling, grinding, CNC, EDM, wire cutting, carving, EDM, lathes, surface Finish, etc. |

| Equipment | CNC, EDM, Cutting off Machine, plastic machinery, plastic part, etc |

| Mould Cavity | One cavity, multi-cavity or same different products be made together |

| Runner System | Hot runner and cold runner |

| Finish | Pitting the word, mirror finish, matte surface, striae |

| Mould Life | 300-500K shots |

| Mould Precision | +/-0.05mm--+/-0.1mm |

| Producing Process | Audit drawings - mold flow analysis - design validation - Custom Materials - mold processing - core processing - electrode machining - Runner system processing - parts processing and procurement - machining acceptance - cavity surface treatment process - complex mode Die - The entire mold surface coating - Mounting plate - mold sample - sample test - sending |

Plastic Mold (Moulds) production process

1. According to 3D drawing or samples for quotation.

2. Including the price of moulds, moulds sizes, material for cores & cavities, weight of product, part cost, payment, moulds lifetime, delivery, etc.

3. After the customer confirming the mould design and quotation.

4. Confirm drawing, start to do DFM,mold flows and mold detail agreed with the customer, start production.

5. Every week we will feedback to the customer a mold progress(picture).

6. We provide the moulds test samples for confirmation(about 10-15 piece), then, get your signature sample ,mass production.

7. Wooden case for moulds, cartons for parts ,or as your requiretment.

8. deliver goods by air or by sea.

Sample Room

FAQ About plastic injection moulding parts

Q1: How many injection plastic mouldings machines do you have?

A1: We have 40 sets of plastic Injection Mouldings machines.

Q2: what are the minimum & maximum unit weight and size your machines can produce?

A2: Our machines produce unit parts from 1 gram to 6000 grams of weight.

Our machines can produce the maximum size of unit plastic part: 1.5*1.5*1.5 meters.

Q3: What kind of plastic materials you usually use?

A3: We are specialized in producing plastic products with the following materials:

PP, ABS,PC,POM,PA,HDPE,HIPE,PS,AS,PBT,PET,PMMA,PVC and so on.

Q4: How do you pack the plastic molded parts?

A4: We pack the plastic molded parts by thick-wall cartons.

If the finished surface of plastic molded parts requires safe protection to avoid scratches, we will use a bubble plastic bag to pack the parts.

FAQ About Worldwide Delivery

Q5: Can you deliver the plastic moulds or plastic products to our factory?

A5: Yes, We have cooperated with many international logistics companies for years.

And we have full experience to manage the delivery directly to the client's factory or appointed warehouse.

|

|

Hot Runner Pp Injection Molding , Mirror Multi Cavity Mold Design Images |