| Sign In | Join Free | My carsrow.com |

|

- Home

- Products

- About Us

- Quality Control

- Contact Us

- Get Quotations

| Sign In | Join Free | My carsrow.com |

|

Brand Name : HOWE

Model Number : HW-418

Certification : ISO9001

Place of Origin : China

MOQ : 1sets

Price : 2000dollars~10000dollars

Payment Terms : T/T, D/P

Supply Ability : 50sets

Delivery Time : 25-30days

Packaging Details : Wood case or carton box

Name : Plastic injection molds

Base material : SKD61、2344、8407、HD、8418、etc

Cavity Multi : 1*1,1+1,1*2,1+1+1,etc

Shot Runner : Cold or Hot Runner, HASCO/DME/YUDO,etc

Design & Program Soft Wares : CAD/CAM/CAE

Mould Life : 300,000 to 1,000,000 Shots

Finish : Pitting the word, mirror finish, matte surface, etc

Mould Standard : DME or HASCO

Tolerance : +/-0.05mm--+/-0.1mm

Mold of steel suppliers : FINKL,Assab,DAIDO,LKM,Buderus

One Stop Maker For Molding And Tooling Service OEM Plastic Mold

Mould Information

| Product name | Multi cavity hot runner injection mould supplier |

| Mould Material | P20,P20H,718,718H,738,738H,2316,M300,S136,S136H,NAK80,CR12,CR12MOV,SKD11,DF-2,SKS3,D2,SLD,DC53,H13,SKD61,2344,8407,HD,8418,FDAC,M2,SKH-9,SKH-51,M35,M42,ASP23 |

| Main Technology | Milling, grinding, CNC, EDM, wire cutting, carving, EDM, lathes, surface Finish, etc. |

| Base material | P20, 2738, 2344, 718, S136, 8407, NAK80, SKD61, H13 |

| Product Material | ABS,PP,PC,PA6,PA66,TPU,POM,PBT,PVC,HIPS,PMMA,TPE,PC/ABS, TPV, TPO,TPR,EVA,HDPE,LDPE,CPVC,PVDF |

| Main Technology | Milling, grinding, CNC, EDM, wire cutting, carving, EDM, lathes, surface Finish, etc. |

| Equipment | CNC, EDM, Cutting off Machine, plastic machinery, plastic part, etc |

| Mould Cavity | One cavity, multi-cavity or same different products be made together |

| Runner System | Hot runner and cold runner |

| Finish | Pitting the word, mirror finish, matte surface, striae |

| Mould Life | 300-500K shots |

| Mould Precision | +/-0.05mm--+/-0.1mm |

| Producing Process | Audit drawings - mold flow analysis - design validation - Custom Materials - mold processing - core processing - electrode machining - Runner system processing - parts processing and procurement - machining acceptance - cavity surface treatment process - complex mode Die - The entire mold surface coating - Mounting plate - mold sample - sample test - sending |

Products Images

Surface Fihish

| Aluminum parts | Stainless Steel parts | Steel | Plastic |

| Clear Anodized | Polishing | Zinc plating | Painting |

| Color Anodized | Passivating | Oxide black | Chrome plating |

| Sandblast Anodized | Sandblasting | Nickel plating | polishing |

| Chemical Film | Laser engraving | Chrome plating | Sandblast |

| Brushing | Carburized | Laser engraving | |

| Polishing | Heat treatment | ||

| Chroming | Powder Coated |

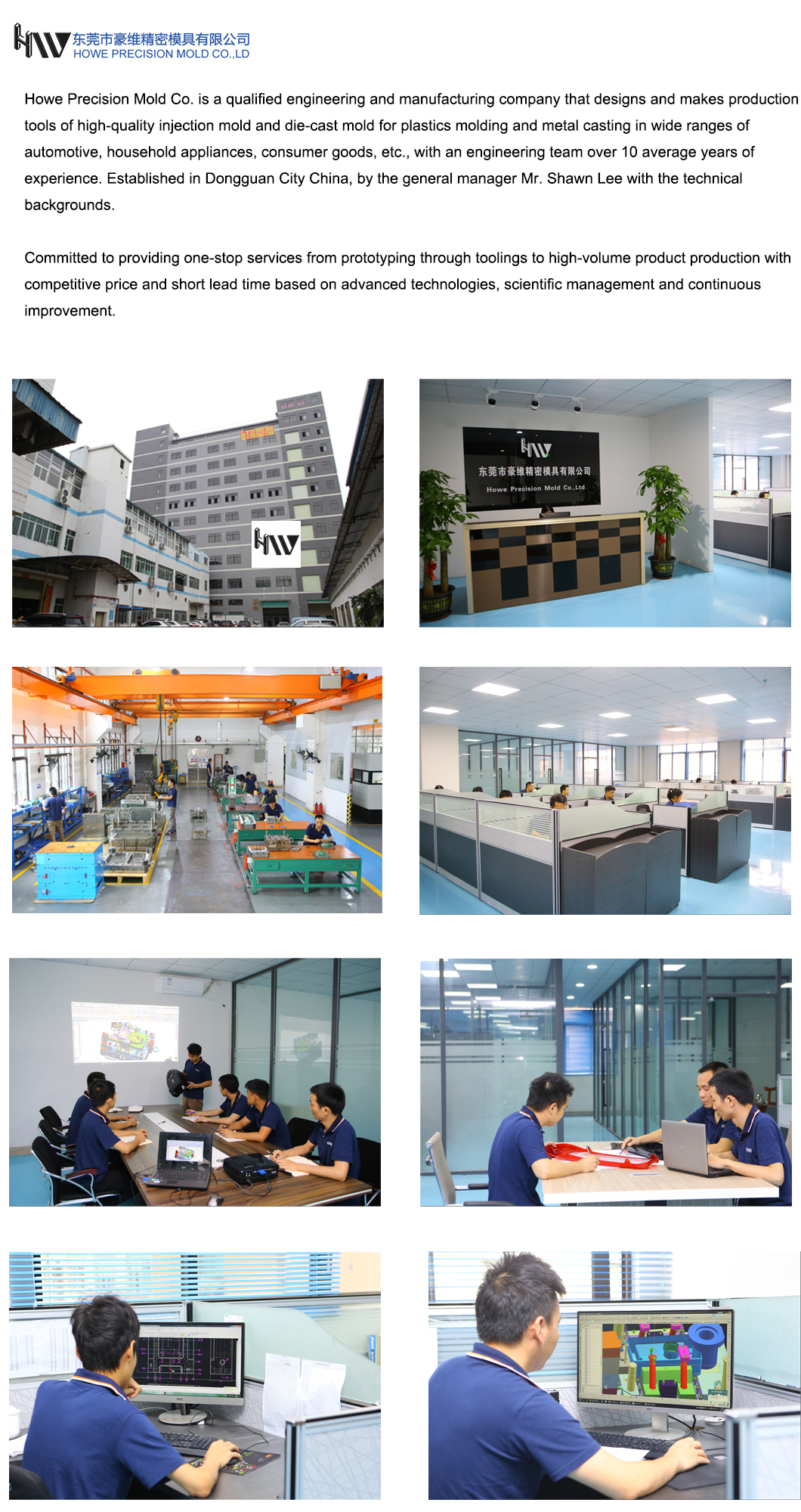

About Us

Work Shop

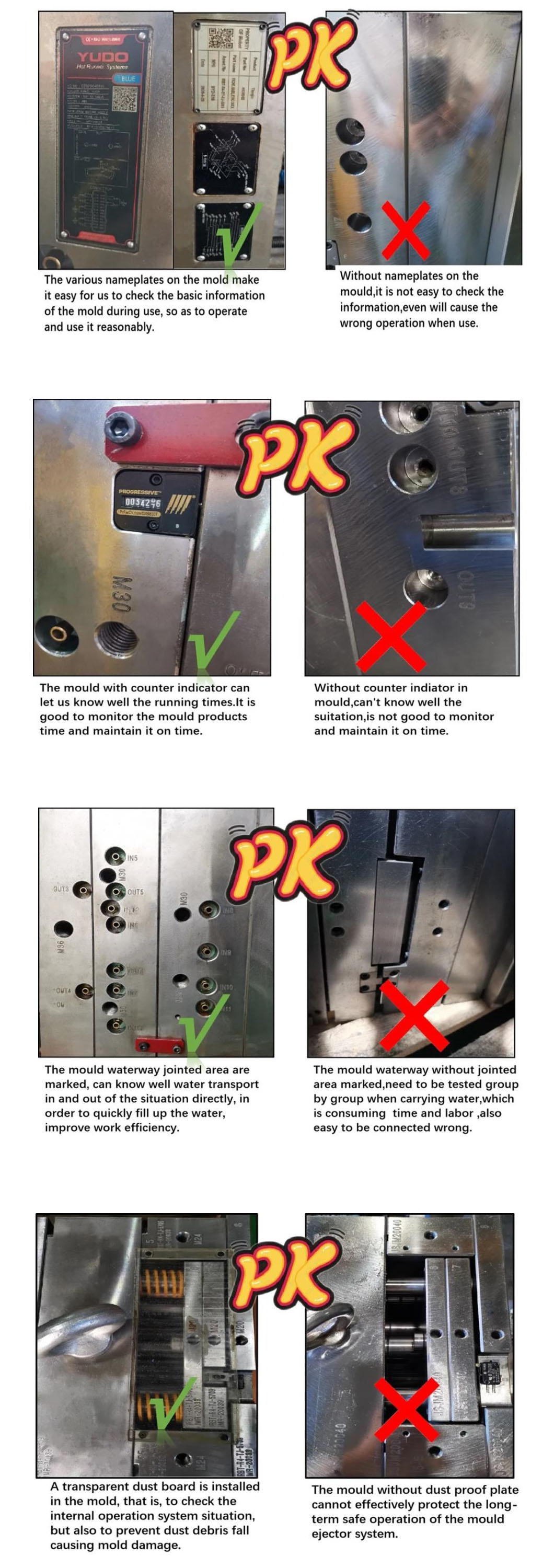

Quality Control

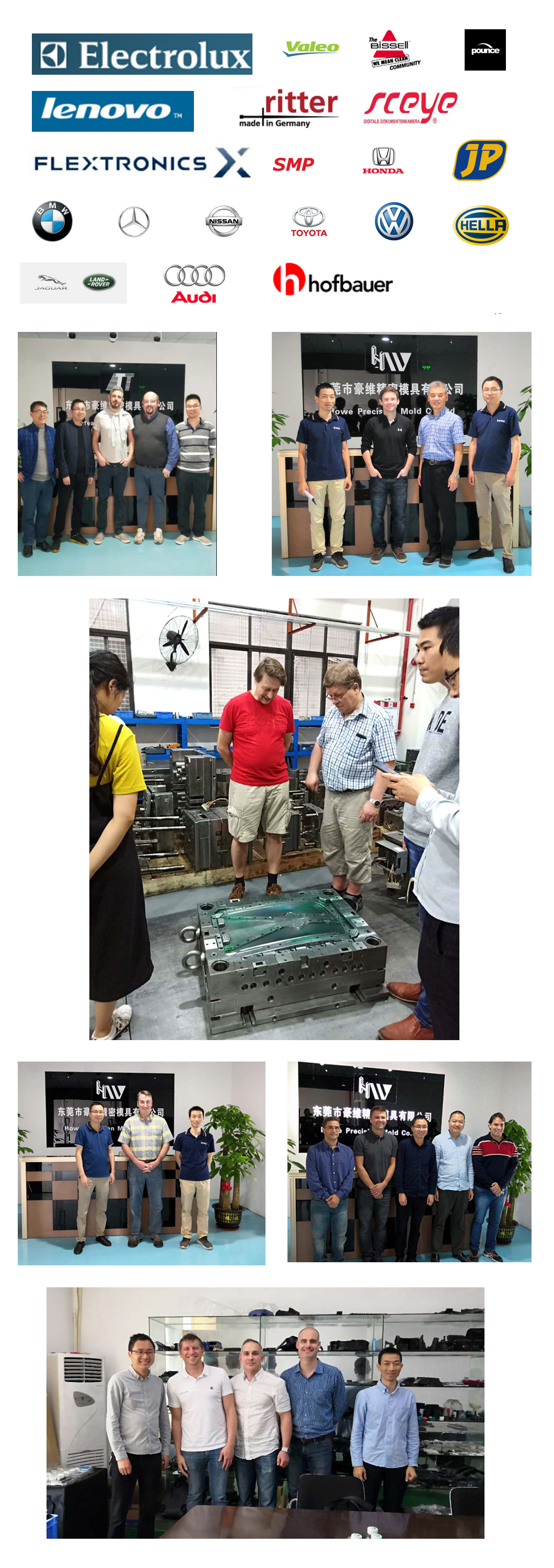

Customer Visiting

FAQ

Q1: Are you manufacturer or trading company ?

A1: We are the manufacturer of Injection moulding parts, our price is more competitive.

Q2: Do you support OEM/ODM service?

A2: Yes, we have a large experienced R&D team, we can offer one-stop service,so welcome to place OEM/ODM orders to us.

Q3: How long is the lead-time for a plastic injection mold?

A3: It all depends on the mold’s size and complexity.Normally, the lead time is 25-45 working days.If the plastic moulds are very simple and in small size, we can work out within 15 days.

Q4: What kind of plastic materials you usually use?

A4: We are specialized in producing plastic products with the following materials:

PP,ABS,PC,POM,PA,HDPE,HIPE,PS,AS,PBT,PET,PMMA,PVC and so on.

Q5: How do you pack the plastic molded parts?

A5: We pack the plastic molded parts by thick-wall export cartons.If the finish surface of plastic molded parts requires safe protection to avoid scratches, we will use bubble plastic bag to pack the parts.

Q6: How does your factory do regarding quality control?

A6: Secure production under strict quality control system; Quality is priority. 100% products tested. CE/ ROHS FCC/ Certification are available if required.

|

|

OEM HASCO Hot Runner PVDF Plastic Injection Mould Tooling Images |