| Sign In | Join Free | My carsrow.com |

|

- Home

- Products

- About Us

- Quality Control

- Contact Us

- Get Quotations

| Sign In | Join Free | My carsrow.com |

|

Brand Name : OEM

Model Number : HW-421

Certification : ISO 9001 , ISO 9000 , ISO 14001

Place of Origin : Guangdong,China

MOQ : 1set

Price : 2000dollars~10000dollars

Payment Terms : T/T,Paypal

Supply Ability : 40set/month

Delivery Time : 20~35days

Packaging Details : wood box,or as your request

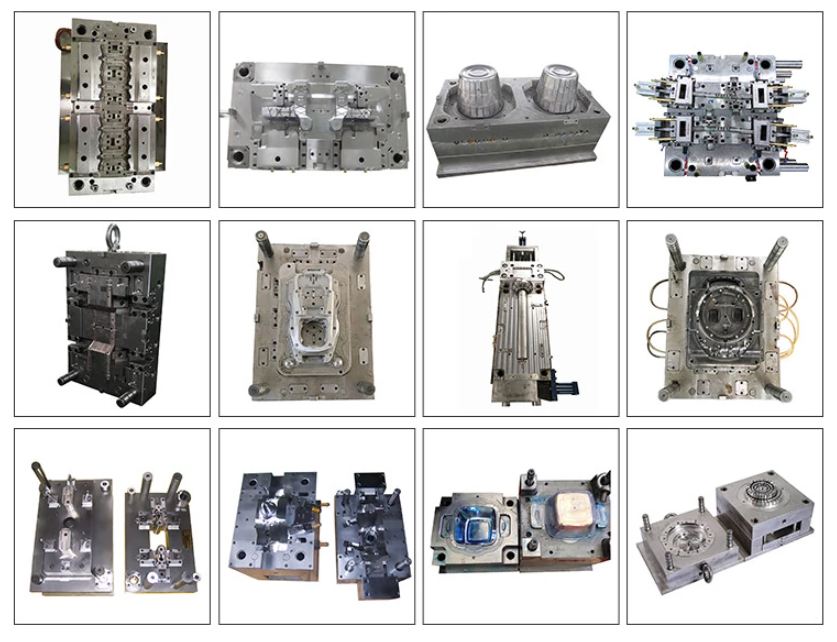

Product Name : Injection plastic mold

Product material : ABS,PA6,PA66,PP,PC,TPU,POM,PBT,PVC,TPE,TPV,TPO,TPR,EVA,LDPE etc.

products range : Electronic products, industrial products, househould products, medical device, petrochemical, auto, aerospace, home appliances, LED lamp parts, agriculture parts.

Color : customized, black, hyaline, custom, etc

Mould life : 200~1 M available

Design software : Solidworks, UG, CAD, Pro-E, CATIA

Surface finish : Texture/Sandy/MT/YS/SPI/EDM finish/smooth/glossy

Colors available : Pantone/RAL and other custom colors

3D Design OEM Thermoforming Thick PP Material Shell Plastic Injection Mould

Per your design concept, Our professional engineers can make drawings and provide design solution to change injection molding.

| Product name | Multi cavity cold runner injection mould |

| Normal Plastic | PP, PE, EVA, PS; |

| Enginnering Plastic | PA, PA6, PA66, PC+ABS, PA46, PA+30% GF, PC, ABS, POM, PBT, TPU, TUR |

| High Engineering Plastic | PEEK, PPS, PPO, PEI, PES, PLA, LCP, antistatic plastic, et |

| Mould size | Any size as per customer's requirement |

| Surface Treatment | Polishing/smooth, Texture/frosted, Printing, Painting, Plating |

| Plastic Color | Nature, white, black, red, yellow, blue,green, as per customer's requirement |

| Products range | Electronic products, industrial products, househould products, medical device, petrochemical, auto, aerospace, home appliances, LED lamp parts, agriculture parts. |

| Lead time | 5-30 working days after receiving deposit or L.C |

| Payment we support | T/T, Paypal |

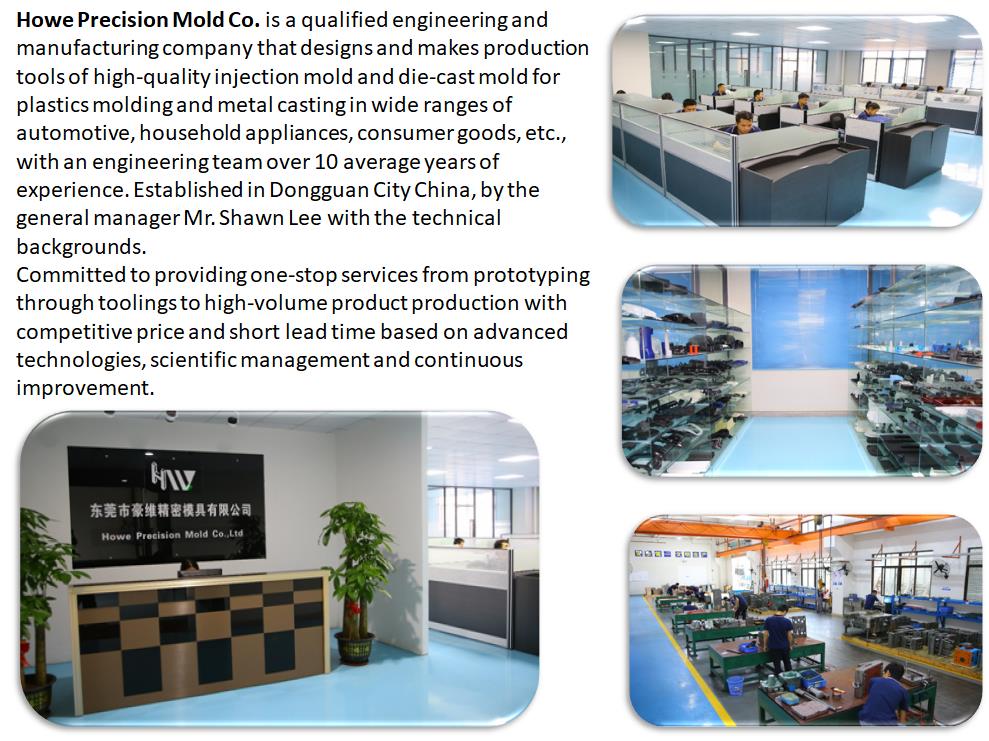

Company Profile

Advantage

1. Manufacturing and exporting experience for nearly 10 years. ISO 9001 approved.

2. Products are supplied to over 20 countries.

3. One-stop service for aluminum profiles, plastic parts, rubber parts, and moulds. Save time and save money for you.

4. In-house mold design and building capabilities.

5. No reclaimed material used to ensure high quality.

6. Keep secret to your idea and your design.

7. 24 hours (two shifts) / 6 days for production.

8. Professional design team, mold maker engineer. OEM/ODM service.

9. Professional QC and R&D teams to assure high quality.

10. Professional sales team. Good English capabilities and communication skills.

11. No MOQ.

12. Prompt delivery. For prototype: 3-7 days. Production orders can be arranged specially to meet customer's urgent demands.

13. Geographical advantages: within 30 minutes to airport or sea port, near to Hongkong.

You can know more about us from www.howemold.com, Looking forward to having a good start for our reliable cooperation!

Work Shop

Quality Meeting

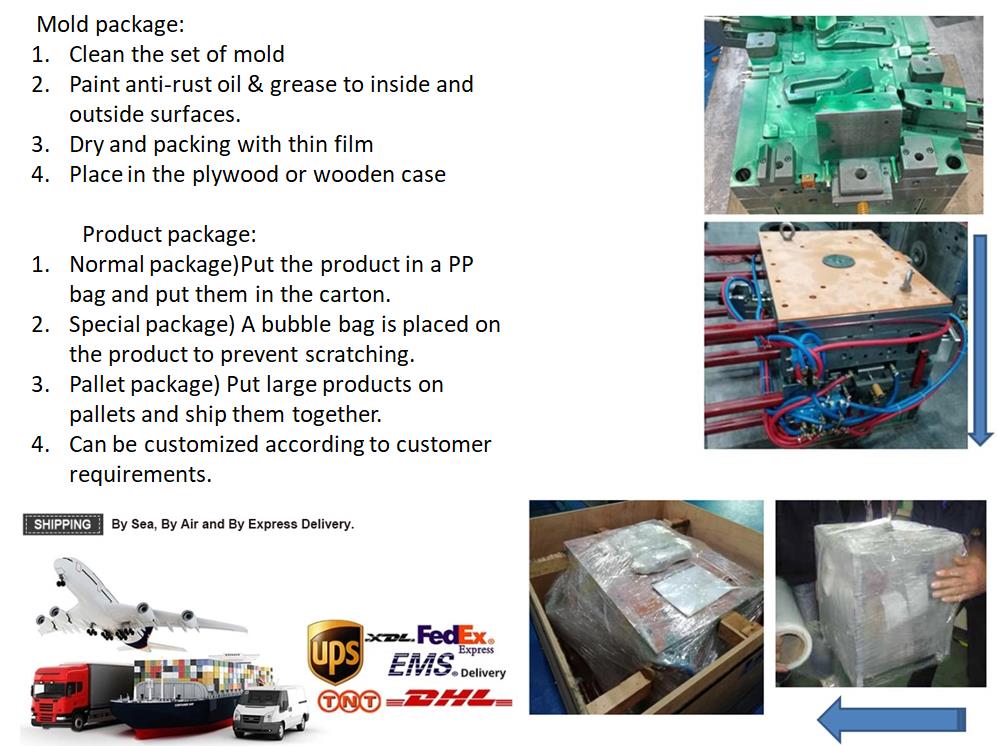

Packing and Shipping

FAQ About plastic injection moulding parts

Q10: How many injection plastic mouldings machines do you have?

A10: We have 40 sets of plastic Injection Mouldings machines.

Q11: what are the minimum & maximum unit weight and size your machines can produce?

A11: Our machines produce unit parts from 1 gram to 6000 grams of weight.

Our machines can produce the maximum size of unit plastic part: 1.5*1.5*1.5 meters.

Q12: What kind of plastic materials you usually use?

A12: We are specialized in producing plastic products with the following materials:

PP, ABS,PC,POM,PA,HDPE,HIPE,PS,AS,PBT,PET,PMMA,PVC and so on.

Q13: How do you pack the plastic molded parts?

A13: We pack the plastic molded parts by thick-wall cartons.

If the finished surface of plastic molded parts requires safe protection to avoid scratches, we will use a bubble plastic bag to pack the parts

|

|

3D Thermoforming Thick Pantone PP Plastic Injection Mold Images |